I think most of us have opened a box of spaghetti or penne without ever wondering what went into making it. It looks simple — flour and water — but behind that neat bundle of dried strands is an entire world of science and engineering. Pasta, in many ways, is one of the quiet success stories of industrial food manufacturing. It’s consistent, shelf-stable, and surprisingly complex once you start looking closer.

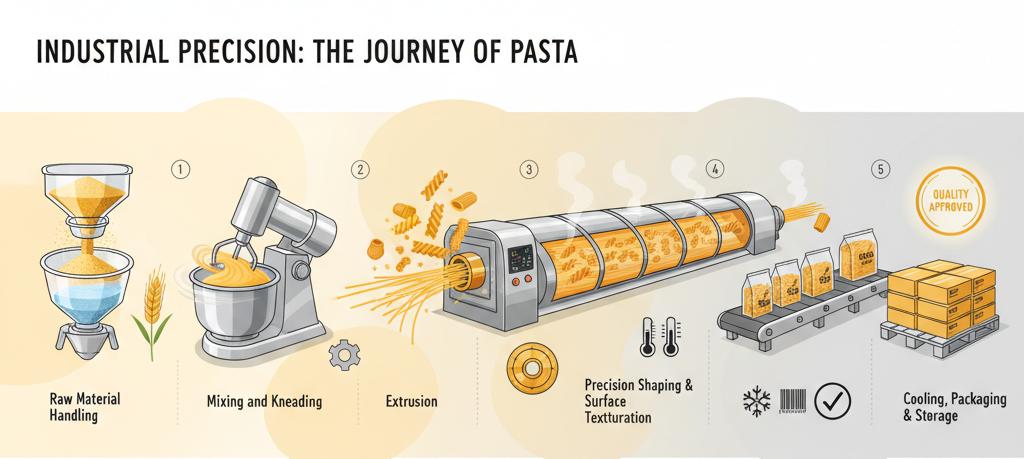

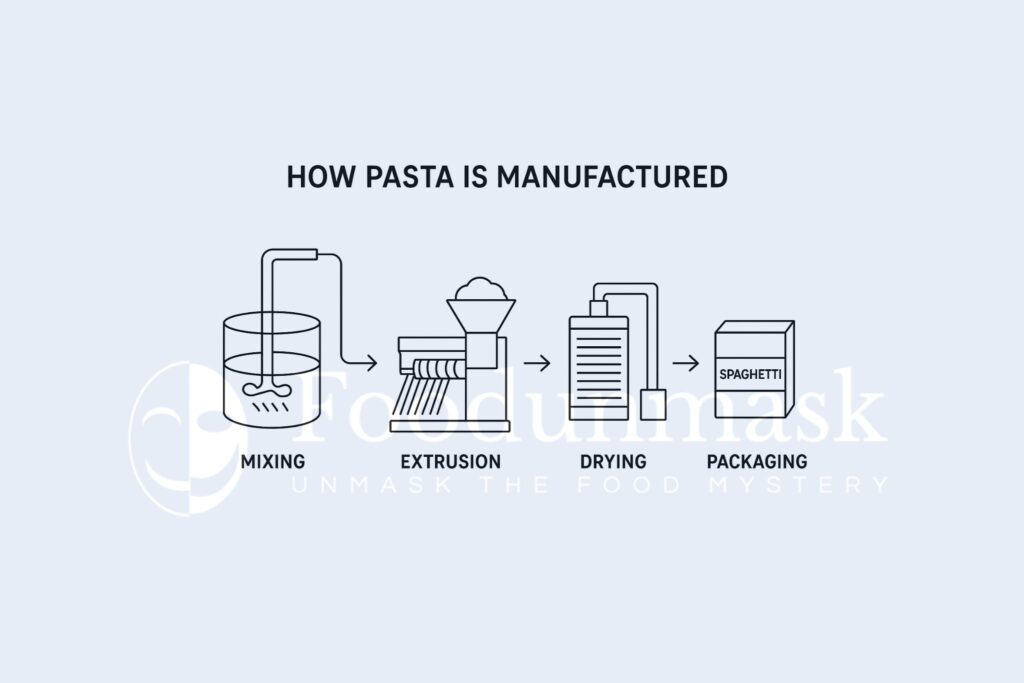

This article explains the step-by-step process of making pasta in modern factories, from wheat to packaging. Some of these processes might seem straightforward, but every part is carefully controlled, often with sensors, automation, and food science guiding every decision.

From Tradition to Industry

People have been making pasta for centuries. It started as a handmade craft — mixing flour and water on wooden tables, cutting sheets with knives, drying them in the sun. Today, that idea remains largely unchanged, but everything else has evolved.

Factories now run continuous lines that can produce several tons of pasta per hour. What used to take a family a full day can now be done in minutes, with almost no human touch. The goal hasn’t changed either: a pasta that holds its shape, cooks evenly, and tastes just right. But I suppose the way we get there has become more about precision and less about guesswork.

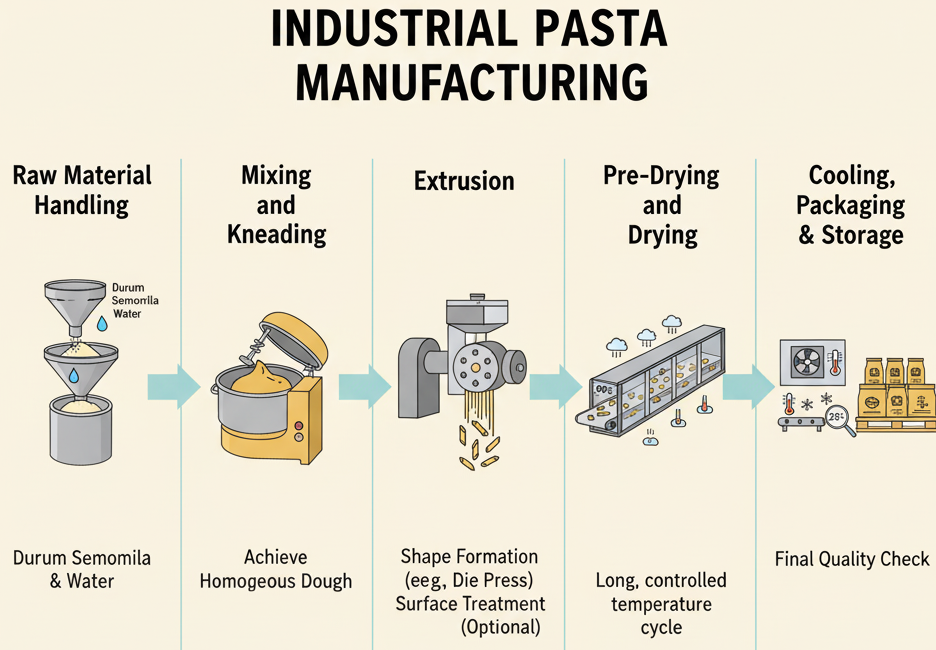

Raw Materials — Where Quality Begins

At the heart of pasta is durum wheat. It’s not the same as the wheat used in bread. Durum is hard, amber-colored, and high in protein, with a protein content of about 11–16%. When it’s milled, it produces semolina, a coarse flour with a yellowish tint. That color is part of what gives pasta its golden look.

Water is the only other ingredient in most pasta. It sounds simple, but it’s not just any water. The temperature, mineral content, and even pH can affect how the dough forms. In some plants, the water is filtered or preheated before use.

For special pastas — like egg noodles or spinach varieties — other ingredients like egg powder, vegetable purees, or natural colorants are added. Flavoring is rare, but possible in gourmet products.

If you ever see “bronze-cut” on a package, it doesn’t refer to the flour. It’s about how the dough is shaped — something we’ll come to soon.

Mixing and Kneading — Building the Structure

The first real stage of production happens in the mixing chamber. Semolina and water are combined under strict ratios — often around 30% water to 70% semolina by weight. Too much water makes the dough sticky; too little and it won’t bind properly.

Modern mixers use sensors and programmable controllers (PLC systems) to measure everything. The goal isn’t to make a smooth dough like bread — pasta dough stays crumbly, almost like damp sand. This helps during extrusion later.

After mixing, the dough moves to kneading units, sometimes under vacuum. Removing air prevents bubbles and cracks during drying. I’ve seen operators describe it as “tightening the dough.” It’s a good description — this step gives pasta its dense, smooth texture.

Extrusion — Shaping the Pasta

This is where pasta becomes pasta. The dough is pushed through a metal die, which has holes shaped like spaghetti, penne, fusilli, or whatever the product is. A screw inside the extruder rotates under pressure, forcing the dough through the die opening.

Each shape has a different die configuration. For spaghetti, the die has hundreds of tiny circular holes. For penne, the holes are diagonal and the tube is cut at an angle. The cutting speed controls length — faster rotation makes shorter pieces.

You might notice that some pasta feels slightly rougher on the surface. That’s because of bronze dies, which leave a coarse finish that helps sauce stick better. Teflon dies, on the other hand, make the surface smooth and shiny. Both are used depending on brand identity.

During extrusion, the dough slightly warms up — around 40–50°C — just enough to make it pliable, but not cooked. The strands are then cut and moved toward drying. Some short pasta shapes are mechanically tossed to prevent sticking before drying starts.

Pre-Drying and Steaming

Before full drying, the pasta goes through a pre-dryer. This step removes surface moisture and sets the shape so pieces don’t deform. Warm air — about 55–65°C — circulates through a tunnel or vertical chamber. The goal is to remove moisture slowly at first. Rapid drying can cause cracks or internal stress.

In some factories, a steam treatment follows pre-drying. It’s a food safety step that kills surface bacteria and stabilizes the product for a longer shelf life. It also helps achieve uniform moisture gradients before the main drying process.

Drying — The Most Critical Step

Drying is really where everything can go right or wrong. It’s also the most time-consuming part. The target is to bring the moisture content down from around 30% to 12–13%. That sounds simple, but it has to be done in stages to prevent cracking, color changes, or flavor loss.

Modern dryers use multi-zone systems with controlled temperature, humidity, and air velocity. Sensors constantly monitor these factors. Some dryers use “high-temperature short-time” methods (HTST) — drying at up to 90°C for 5–6 hours. Others prefer “low-temperature long-time” (LTLT) drying — around 55°C for 12–20 hours — which gives a more natural color and flavor.

I’ve noticed that even within the same company, different plants might use slightly different drying profiles. It depends on equipment, climate, and product type. What matters is consistent moisture distribution and firm texture after cooking.

Cooling and Conditioning

Once drying ends, the pasta is cooled slowly to avoid condensation. Sudden temperature drops could cause it to absorb moisture again. The cooling area looks like a quiet tunnel where air circulates gently.

After cooling, the pasta rests in conditioning silos for a few hours. This equalizes internal moisture. It’s a small detail, but it makes a big difference. Pasta that’s not conditioned properly tends to break during packaging or shipping.

Quality Control and Food Safety

Every batch of pasta passes through several checkpoints. Some tests are done automatically — for example, optical sensors detect color or shape irregularities. Others are manual: small samples are cooked and tested for texture, elasticity, and taste.

In a lab setting, parameters like moisture content, protein level, ash content, and cooking loss are checked. Microbial testing ensures the product meets safety standards. HACCP systems track every stage, from raw material intake to packaging.

Each pasta pack passes through a metal detector to identify any metallic contaminants (ferrous, non-ferrous, or stainless steel). For non-metallic contaminants like plastic or glass, advanced facilities may integrate X-ray inspection systems to ensure product safety.

Further, as a food professional, you can read this document by the National Pasta Association for Salmonella control in dry pasta facilities.

Packaging and Labeling

Packaging protects the pasta from moisture and contamination, but it also tells a story.

Dry pasta is usually packed in polypropylene or laminated film bags. Some brands now use biodegradable or paper-based films to reduce environmental impact.

Before sealing, packaging machines often fill bags under controlled air conditions to reduce oxygen, improving shelf life. Each package gets a printed batch code, best-before date, and regulatory information.

Labeling rules vary slightly by region, but almost all countries require ingredients, nutrition information, allergens, and storage instructions. Many factories now have automated vision systems that verify correct labeling before the packages are boxed.

Modern Innovations in Pasta Manufacturing

If someone from 1900 saw a modern pasta plant, they’d probably think it’s something out of science fiction. Machines now talk to each other, self-correct parameters, and alert operators through software dashboards.

A few innovations worth noting:

- Industry 4.0 Integration: Real-time monitoring, remote control, predictive maintenance.

- Energy Recovery Systems: Waste heat from dryers reused for preheating air or water.

- Gluten-Free Pasta Lines: Using rice, lentils, or corn flour, often needing customized extrusion and drying programs.

- Sustainable Packaging: Compostable films, reduced plastic use, lightweight cartons.

Automation hasn’t just improved efficiency; it’s made product consistency far more reliable. I’d say it also allows producers to experiment more — small recipe changes can be tested digitally before actual production.

Common Challenges and How They’re Solved

Even with automation, pasta manufacturing isn’t foolproof. Machines can misbehave, ingredients vary, and tiny shifts in humidity can affect outcomes.

Here are a few typical problems:

| Problem | Likely Cause | Correction |

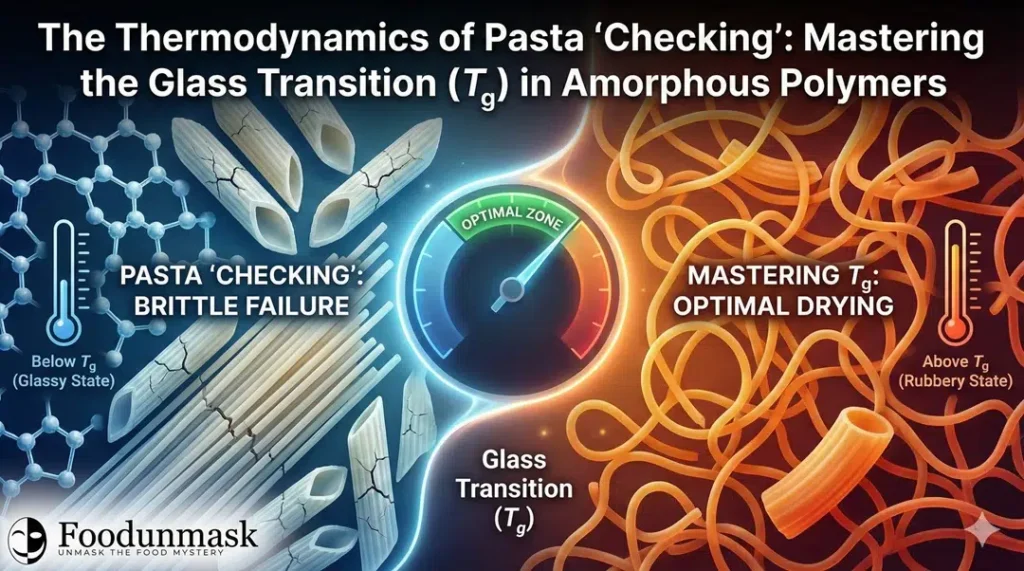

| Cracking during drying | Too rapid moisture removal | Adjust drying curve; lower air velocity |

| Sticky pasta | Excess water or low drying temp | Optimize mixing ratio or extend drying |

| Pale or grey color | High-temperature oxidation | Control air composition and drying time |

| Uneven shapes | Die wear or dough inconsistency | Replace dies; adjust kneading time |

Most plants have engineers or food technologists constantly tuning these parameters. Sometimes it’s a matter of intuition — understanding how dough “feels.” Machines help, but experience still counts.

Sensory Quality and Consumer Perception

No matter how advanced the process, what ultimately matters is how pasta feels and tastes when cooked. Texture, or al dente firmness, depends on protein quality and drying profile. Color comes from the natural pigments in semolina. Smell, though subtle, changes if heat treatment is excessive.

Sensory panels — real people — test batches regularly. They look for stickiness, chewiness, flavor uniformity, and even sound (yes, the snap of dry pasta can indicate brittleness). It’s part science, part art.

Sustainability and the Future

The pasta industry is relatively efficient compared to many other foods. But there’s room for improvement. Water use during cleaning, energy for drying, and packaging waste are still challenges.

Many manufacturers now invest in heat recovery, solar-assisted dryers, and closed-loop water systems. Some are experimenting with AI-controlled extrusion lines that adjust torque and speed automatically based on dough resistance.

And then there’s innovation in 3D-printed pasta — not quite mainstream yet, but it’s being explored for customized shapes and nutritional profiles.

I suppose the core idea hasn’t changed much. We still mix flour and water. But the tools, the precision, and the awareness behind them have grown beyond imagination.

Conclusion

Pasta manufacturing today is a fascinating mix of old wisdom and modern technology. The ingredients are still basic — semolina and water — but everything else is a balance of physics, chemistry, and engineering.

Every strand of spaghetti or shell of penne goes through dozens of control points before it reaches your kitchen. When you see pasta neatly packed on a supermarket shelf, you’re really looking at the result of a century of quiet industrial progress.

It’s funny — something so simple can be so technical. And maybe that’s the beauty of food science. It hides complexity in plain sight.

Pingback: Hydrocolloid in Gluten-Free Pasta: Engineering the "Fake" Gluten Network

Pingback: The Thermodynamics of Pasta: Understanding Tg - Foodunmask.com